Production of polyethylene pipes

Polyethylene pipe products are widely used in installation, repair and reconstruction of domestic and industrial pipelines. A special production technology allows to preserve all the positive qualities of plastic, adding stability to the pressure of any working environment

Materials: PE 100, PE 100+, PE 80, PE 100RC

Materials: PE 100, PE 100+, PE 80, PE 100RC

Advantages of the material

Corrosion resistance

Service life for more than 50 years

Sanitary and hygienic, environmental safety

Low roughness and practical absence of pipe overgrowth

High durability to hydroabrasive wear

High chemical resistance

Stability to hydraulic shocks

Stability to the influence of vagus currents (does not conduct current)

Low pipes weight

Ease of transportation

Strength of welded joints that exceeds the strength of pipes themselves

High maintainability

Multilayer pipes for water supply

-

Double-layer pipe

Double-layer pipe

Outer layer

Material: polyethylene PE 100 RC

Increased strength minimizes possible pipe damage and serves as an indicator of pipe damage degree

Inner layer

Material: polyethylene PE 100 -

Three-layer pipe

Three-layer pipe

Outer layer

Material: polyethylene PE 100 RC

Increased strength minimizes possible pipe damage and serves as an indicator of pipe damage degree

Middle layer

Material: polyethylene PE 100

Inner layer

Material: polyethylene PE 100 RC

Increased strength protects pipe from tension arising from the action of solid debris contained in the local soil; trench laying of pressure pipelines with backfilling is allowed

Point load effect on the pressure pipe

Point loads may occur at the point of contact pipe with sharp inclusions of the soil or fragments of old pipelines. Soil pressure is transmitted through such inclusions unevenly,and the maximum tension develops near the inner surface of the pipe. Joint action of external point loads and internal pressure in the pipe leads to cracks on the inner surface, which subsequently lead to the destruction of the pipe

Laying of polyethylene multilayer pipes

| Installation of pipelines using multilayer pipes made of PE 100, PE 100 RC materials is carried out similarly to pressure pipes made of PE 100. When transporting and storing pipes, it should be laid on a flat surface of vehicles, without sharp protrusions and irregularities to avoid damage to the pipes. Comply with GOST 18599, as well as SM EN 12201-2+A1:2016, and are widely used in drinking water supply and land reclamation networks |

Pipes are used

When trenching without using sand backfilling

With puddle or rotary laying

When laying in unstable and water-saturated soils

Using trenchless technologies

In rocky, gravel-pebble, crushed stone and other soils with the inclusion of the above ones

-

Double-layer pipe is recommended for use:

- Traditional trench gasket with

- sandy or clay soil

- "Pipe-in-pipe" reconstruction in good condition of the inner surface of the renewable pipe

-

Three-layer pipe is recommended for use:

Three-layer pipe is recommended for use:- In all application areas available

- for double-layer pipe

- For trenching of pressure pipelines

- with backfilling

- For trenchless recovery

- In case of open laying without

- replacing the backfill soil

Pipes supply

In the bays

100, 200m

100, 200m

In sections of 12 m

or by customer

agreement

or by customer

agreement

Diameters

16-450 mm

16-450 mm

Temperature of transporting area from 0 to 40 C

SDR

11; 13,6; 17; 21; 26

11; 13,6; 17; 21; 26

Working pressure

below PN 25 (25 bar)

below PN 25 (25 bar)

Service life more

than 50 years

than 50 years

Guideline documentation GOST 18599-2001 SM EN 12201-2+ A1:2016

Advantages

Tightness during the entire service life

Low and unchanged roughness, no sediments and overgrowths

High chemical resistance, no corrosion

Stability to dynamic and static loads, seismic resistance

Safety for drinking water supply

Low weight

Areas of application

Connection of houses

Intra-quarter water supply networks

Urban water supply networks

Water supply highways

Connection variants

Hover over the «step» to visualize it.

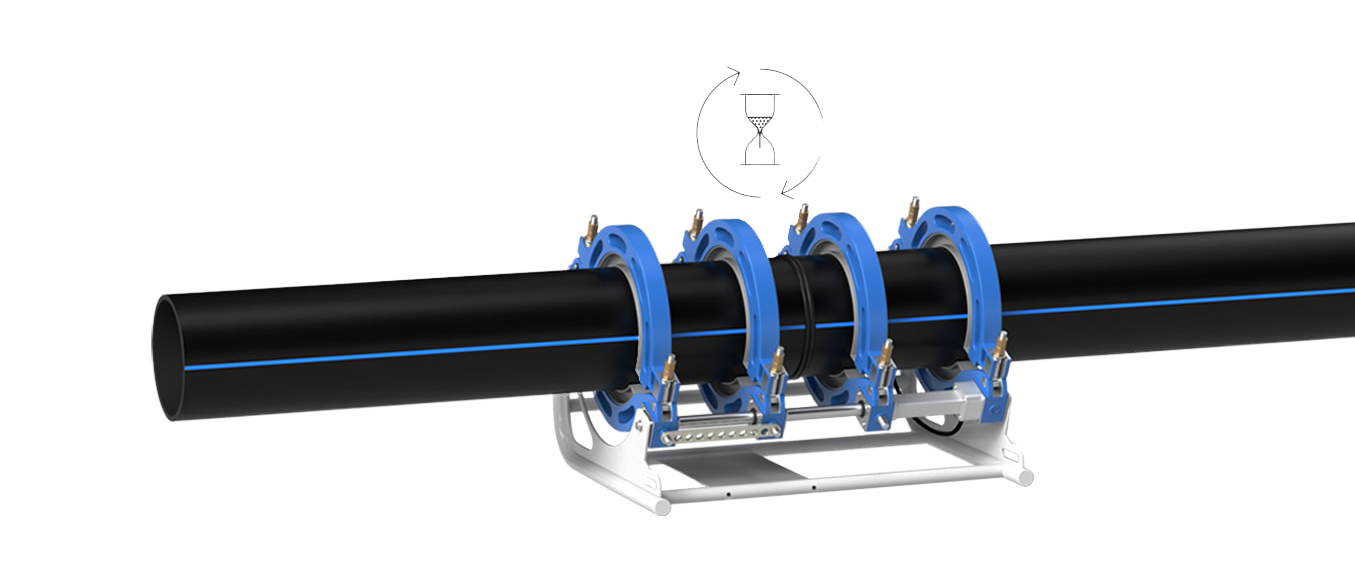

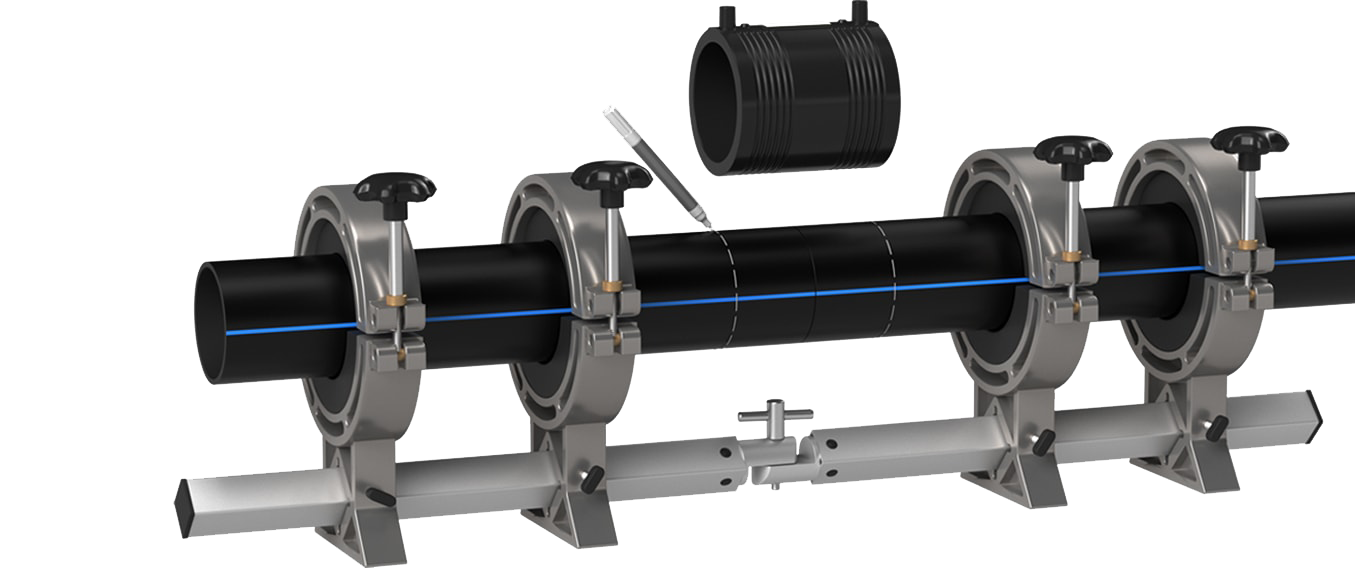

Method 1 - Joint welding

The area is cleared of debris and protected from precipitation (a tent should be installed)

The ends of the pipes installed in the centralizer are cleaned of dirt, the pipes are placed along the axis and fixed in the welding machine

In the device is installed ТОРЦЕВАТЕЛЬ , the contacting surfaces of the pipes are treated, the end face removed and the displacement of the pipe edges is adjusted (the norm is less than 10% of the wall thickness)

The heater is installed, the pipes are seized up and melted, the heater is removed

Pipe ends are seized up and kept under pressure until cooled

Welding is ready

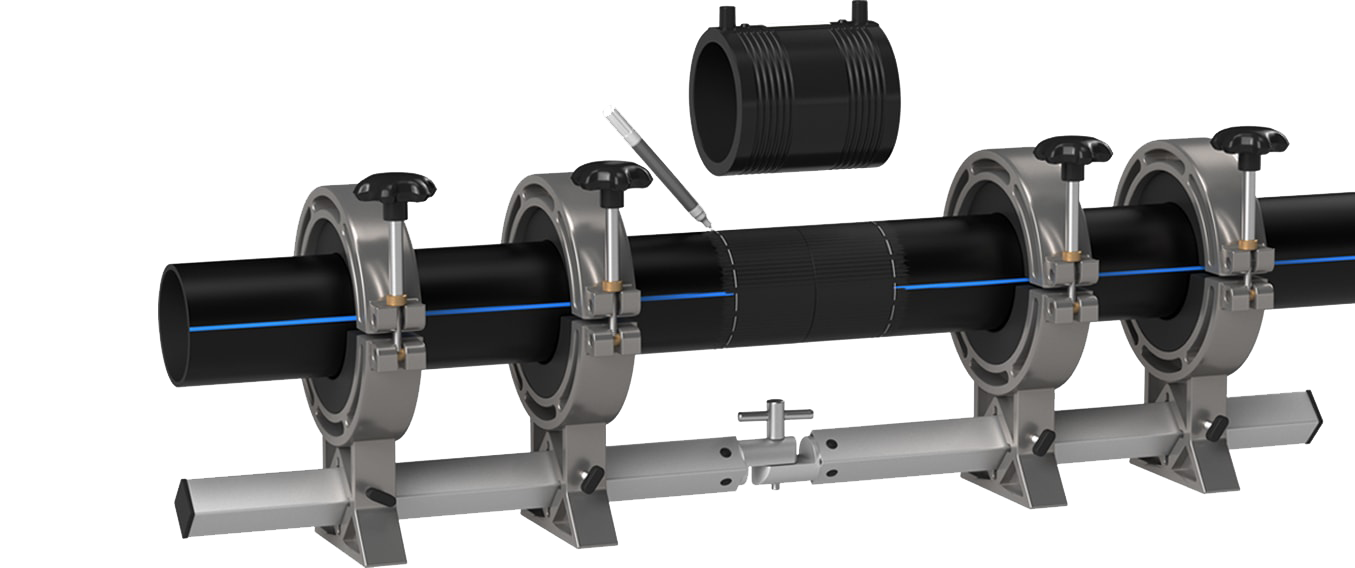

Method 2 - Welding with parts with mortgage heaters

Preparation for installation. Area is freed from garbage and protected from precipitation (a tent is installed). The pipes are cut off at right angle

Pipes are fixed with a positioner or improvised means.

A label is placed.

A label is placed.

With the help of a stripping tool, the oxide layer is removed from the pipe, the contacting surfaces of the pipe and the fitting are degreased.

The mark is resumed.

Pipes are installed inside the part (fitting) by tags.

The connection is fixed with a positioner or improvised means. The welding machine is connected.

The connection is fixed with a positioner or improvised means. The welding machine is connected.

Welding parameters are entered into the device using a barcode scanner or manually. Welding takes place automatically.

The connection is maintained by the time required for cooling

Welding is ready

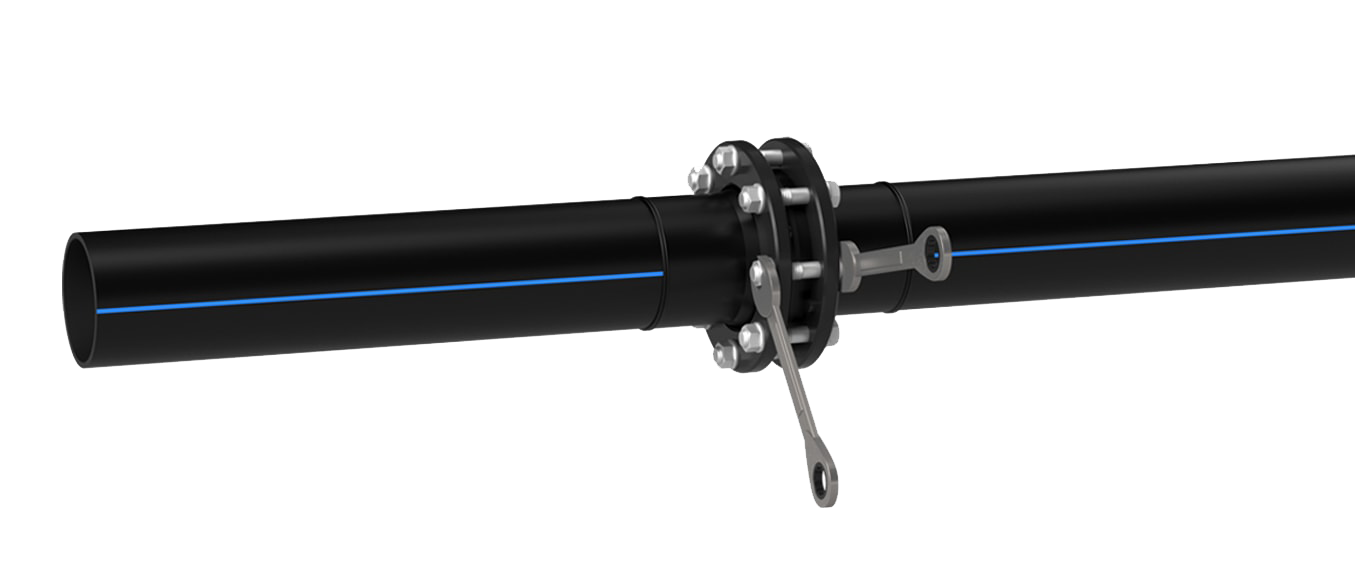

Method 3 - Disassembly connection using compression parts

Preparation for installation. The pipes are cut off at right angles

Pipes are inserted inside the fitting to the end

The nut is tightened with the maximum possible force. A special tool is used for pipes over 32 mm

Assembling is ready

Contacts

Do you want to make order?

Fill the callback form and our manager will contact you to clarify details.

Working hours:

Mon-Fri from 9:00 to 17:00

Production

Address:

Moldova Republic, Grigoriopol region, Mayak city

Office

Address:

Phone:

E-mail:

Phone:

E-mail:

Moldova,Tiraspol city,

str. Profsoyusov ,50

+373(533)9-31-45

+373(533)2-51-37

office@polimir.org

str. Profsoyusov ,50

+373(533)9-31-45

+373(533)2-51-37

office@polimir.org